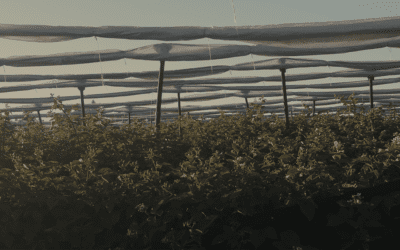

Based in Gresham, Oregon, Scenic Fruit Company is one of the oldest berry processors in the Northwest. Along with packing and contract packaging, Scenic Fruit offers a variety of value-added capabilities and approaches required for the more competitive natural and organic foods market segments. Founded in 1931, Scenic Fruit Company delivers quality through experience to its customer base.