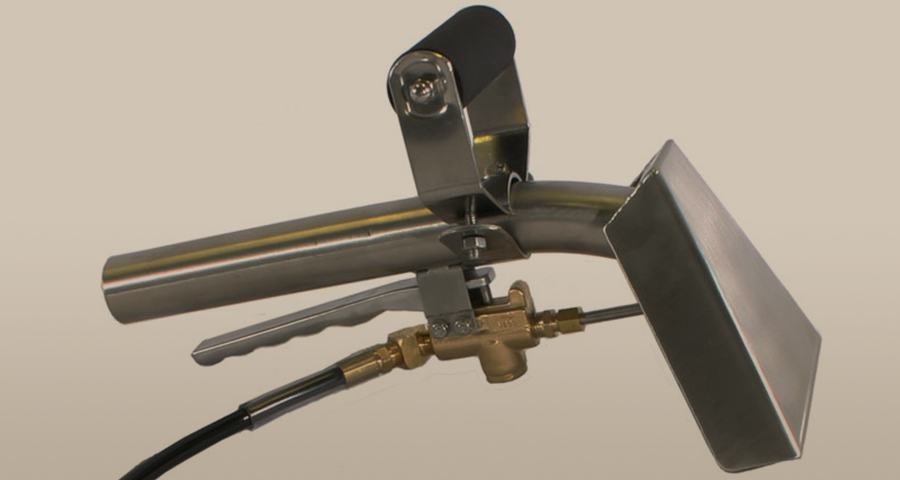

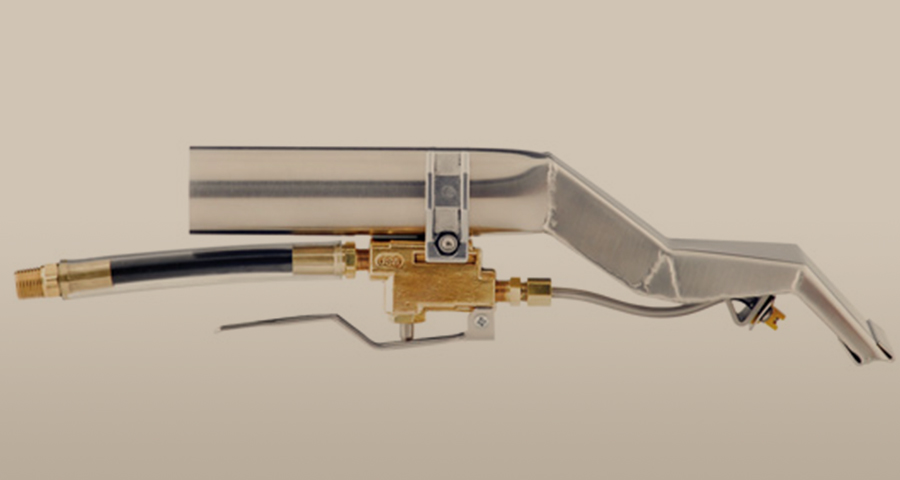

Since its founding in 1976, Production Metal Forming, Inc. (PMF) has been a premier manufacturer of tools and parts for the worldwide carpet cleaning industry. This family-owned business operating out of Klamath Falls strives to treat its customers with the highest respect while producing quality components with tremendous care and attention to detail. Production Metal Forming, Inc. has been a benchmark of standards when it comes to creating specific tools for upholstery, stairs & crevices, cleaning wands, valves & repair kits, component accessories, and hardware. They create not only their own brand of products but also products for other major carpet cleaning brands in the industry as well.

Success Story

Production Metal Forming Inc

Industry

Location

Date Founded

Number of Employees

Background

20%

Increased

Improved

The Situation

With the cleaning products industry in decline, sales at PMF began to slowly lag. PMF owners desired to build an efficient company that would require less day to day involvement on their part. They wanted to secure the future growth of PMF to be able to withstand economic and industry forces. As part of the initial assessment, OMEP worked with PMF to identify key inefficiencies in the manufacturing process, including long cycles times, a buildup of work in process, and a high rate of rework.

The Solution

OMEP developed a short-term plan for growth to ensure maximum and immediate impact. As part of this strategic growth model, the owners hired a new General Manager, freeing up time usually spent on smaller day-to-day tasks. With OMEP’s help, Production Metal Forming, Inc. was able to adopt and apply lean principles that improved the inefficient areas within their manufacturing processes. They implemented a visual scheduling system, engaged in 5S Organization, and implemented Kanban systems. Workflow improvements were created throughout the plant, including a more efficient layout for their weld shop.

The Results

As a result of these new practices Production Metal Forming, Inc. saw a 20% reduction of on-hand inventory. The company was also able to improve its rate of on-time deliveries while reducing rework. Through lean implementation and new workflows, PMF improved cross-functional communication among their team.

The new General Manager is now able to oversee day-to-day operations, giving the owners relief from daily activities. All these improvements have helped to spur on the growth PMF was ultimately looking for. With a solid plan in place and a team that is empowered to continuously solve problems, PMF is poised for a successful long-term future.

It was an amazing experience working with the OMEP consultants over the last year. After 42 years in manufacturing, we needed fresh eyes on our processes. OMEP consultants taught our crew Lean concepts, 5S, and Kanban systems and transformed us into a much more efficient company.