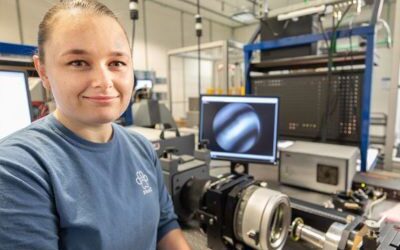

A second-generation, family-owned small business located in HUB-Zone designated rural Bandon, Oregon, Hardin Optical Company is a manufacturer of precision optical lenses with commercial and defense applications. Some of their most specialized products are manufactured to excruciating micrometer-level tolerances that cannot be measured using conventional industry mechanical metrology.

Success Story

Hardin Optical Company

Industry

Location

Date Founded

Number of Employees

Background

Productivity

Job Creation

Sales Improved

The Situation

The company was facing a series of small challenges that imposed a level of stagnation that was eroding the bottom line – first-pass yield was declining, employee turnover was up, margins were narrowing, the customer base defied growth, and small-run projects were sacrificing profitability.

The Solution

In coordination with Hardin, OMEP developed a comprehensive series of projects, including: operational improvements in the two most important production lines; implementation of a new ERP to provide better clarity with data in real time; employee development to nurture talent and invest in the workforce; supervisor coaching to provide leadership skills and practical expertise in lean practices; revised and updated standard work, review of strategic plan and critical roles; and a reorganization of the Business Development and Quality Management practices to better align with the strategic and operational plans.

“The OMEP team members have a broad suite of valuable skill sets,” said Vice President and General Manager of Hardin, Martin Mather. “Their expertise helped close gaps in Finances, Process Development, and Process Control & Documentation. The way the team members steer, coach, and mentor drives improvement and creates employee ownership. It has been a very successful partnership, and the results are clear to see with reduced costs, improved delivery, and sustained or improved quality.”

The Results

While this ambitious multi-year plan took dedication, it delivered a business transformed, with the following high-level impacts:

- Top performing of three critical defense article suppliers.

- Improved productivity, with 100% OTD and zero returns with their largest customer – over 300,000 precision, hand-made parts.

- Creation of 10 new jobs.

- Sales improved with a 250% and 300% increase with two different Tier 1 defense suppliers and record-setting revenue in 2023.

- Asked to produce new prototype components for next-generation DoD platforms.

- ERP unlocked data-driven decision making, transforming production and financial analysis.

“[OMEP's] expertise helped close gaps in Finances, Process Development, and Process Control & Documentation. The way the team members steer, coach, and mentor drives improvement and creates employee ownership. It has been a very successful partnership, and the results are clear to see with reduced costs, improved delivery, and sustained or improved quality."