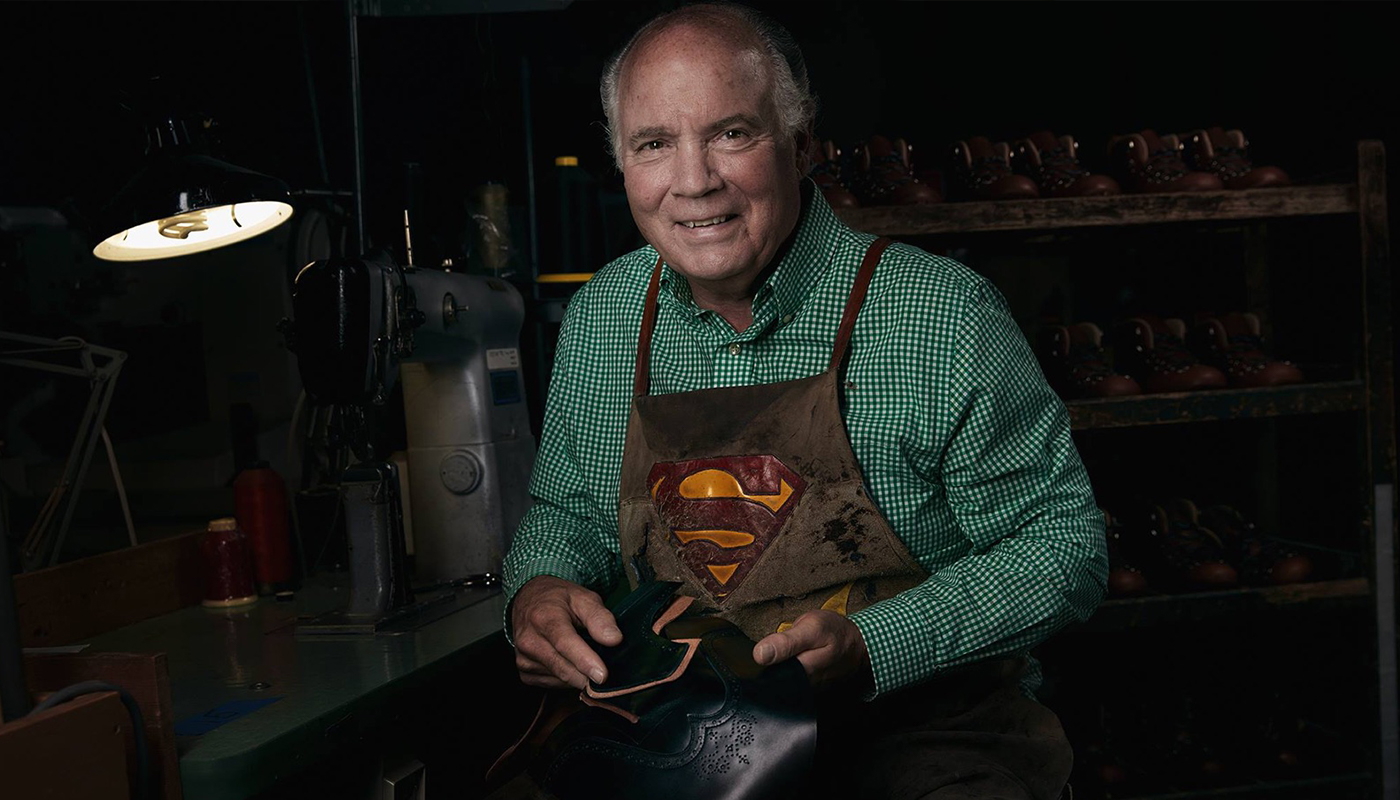

After honing his skills at his father’s company, Danner Boots, Bill Crary founded Crary Shoes in 1978 to provide high-quality orthopedic custom shoes. Crary Shoes is one of the last remaining custom orthopedic shoemakers who still manufacture in the United States. Every pair of custom shoes is made in their factory in Portland, Oregon. They are proud to combine old world quality craftsmanship with new world technology & efficiency. Although shoes are their product, their value proposition is to problem solve and improve the quality of life for those with challenged feet.

Success Story

Crary Shoes

Industry

Location

Date Founded

Number of Employees

Background

Retained

All Jobs

$100,000

The Situation

As is the case with many manufacturers who reach out to OMEP, Crary Shoes was in the process of considering a move to a new facility, as they had begun to outgrow their existing location. In the process of setting up the new facility, Crary Shoes wanted an advisor to help them set their new factory up as a lean manufacturing facility, maximizing their workflow and ensuring that they grow, in the best way possible.

The Solution

The OMEP team began by introducing the team at Crary Shoes to the principles of lean manufacturing. This custom training involved not only educating employees about how to use lean as a business operating philosophy, they actively completed projects on their facility that had an immediate real-world impact to solidify their learnings.

A current state value stream map and shop floor layout were created to get a sense of how information, products and processes flowed in the existing facility. Value stream mapping (VSM) is a diagnostic tool used to identify waste and improve material and information flow throughout the organization. The current state map was used to inform the Future State layout of the new facility, accommodating growth for both patient care capacity and manufacturing capacity. 5-S Disciplines were introduced to help the Crary team identify which items were essential to their business as well as to help optimize their locations for a potential move.

OMEP’s team-based support included assisting Crary Shoes with final preparations for the move, as well as support after the move into the new space. Once they moved into the new space, the new layout was optimized, utilizing the value stream map and shop floor layout OMEP had already prepared.

The Results

Crary shoes is now set up for optimal flow in their new 6344 square foot facility. By doing more with the same amount of people, and eliminating material waste by reducing defects and obsolescence, they have established the potential to save $100,000. Capacity was created as a result of improvements, which in turn can now be filled with new sales. Their existing sales have been retained and the organizational and manufacturing design can now support sales and be scalable for the future growth of over $3M in additional sales.

With the continuing help of OMEP, Crary is currently in the process of creating training modules for different jobs within our factory in order to train new hires, as well as cross-train current employees. This cross-training helps facilitate a better understanding of the whole process for the team, as well as relieving resulting bottlenecks when team members are on vacation or out ill.

Having an outsider's perspective was extremely helpful in seeing our processes in a new light.