Our approach addressed immediate concerns while also building a foundation for long-term and sustainable growth. We introduced three key initiatives:

- Create standard work and a training system

We helped AMPCO create standard work for 17 processes. Standard work is a combination of workplace visuals and documentation that includes the preferred method of doing a job. Creating standard work and training to that standard creates a repeatable sequence of events to do a job.

OMEP also implemented Train the Trainer to help improve overall readiness for new hires, ensuring that the procedures would be followed in the same way for years to come.

- Improve work in progress level visuals and inventory locations

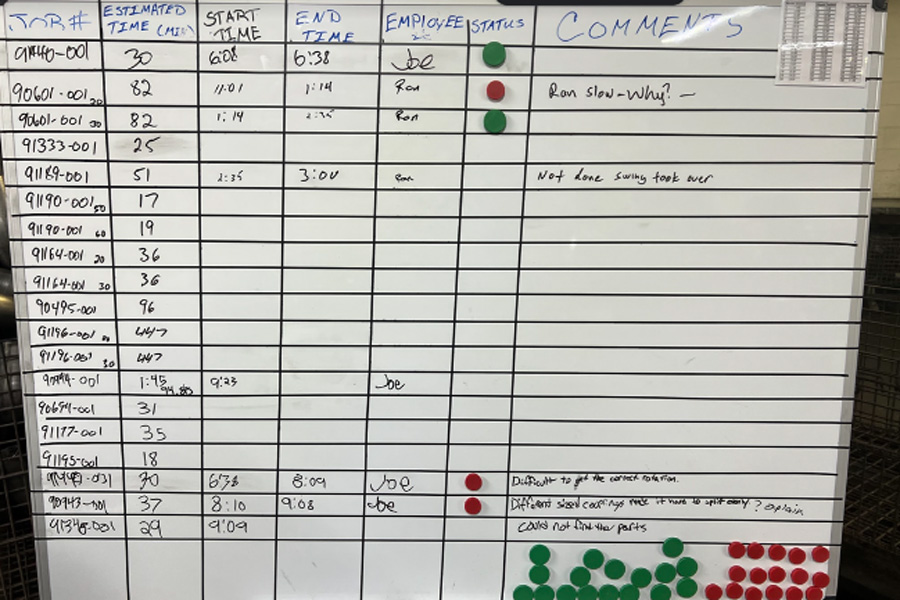

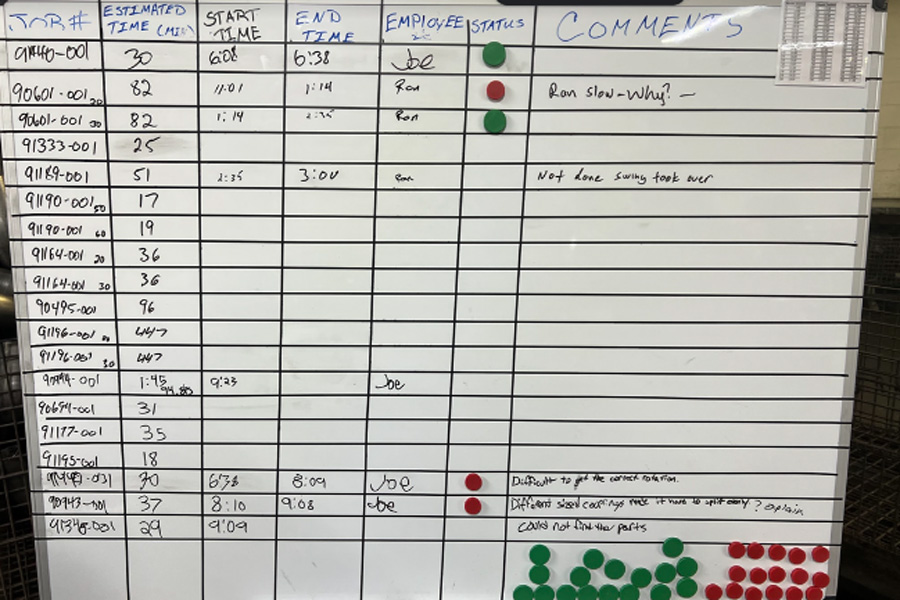

In order to create a more sustainable system, we instituted more visuals including daily accountability boards to track daily output, backlog, personal availability, and to highlight any obstacles. Using these boards helped leadership and employees communicate to reduce backlog and meet daily demands.

- 5S Training and Methodology Implementation

5S is a technique for workplace organization that provides for a well-organized, safe, and efficient workplace. This standard of creating an organized workplace is a “lean fundamental” that is necessary for innovation related to all other lean efforts.

Observing and Maintaining Changes

As these strategies were implemented, the atmosphere at AMPCO began to shift. The daily accountability boards became hubs of interaction. 5S methodology brought a sense of order and pride to the workspace. Standardized work instructions bridged gaps that had previously caused confusion.

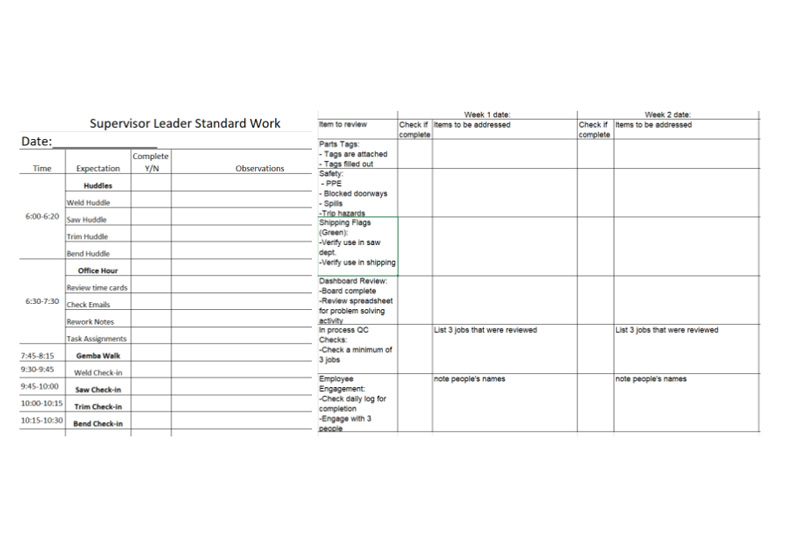

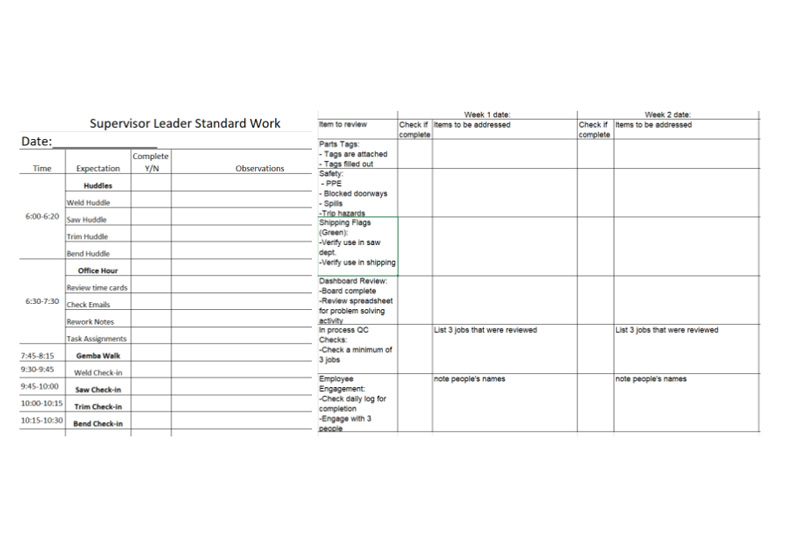

To maintain changes, leaders’ standard work was implemented. A manager takes weekly Gemba walks on the production floor, making sure the process is working as defined: accountability boards being filled out correctly, 5S still intact, and WIP is organized. Once a month, other leadership walk the floor together to ensure that processes are still being followed. Any problems are taken care of proactively.