OMEP will help manufacturers engage with the federally funded, billion-dollar research and development program Manufacturing USA. We are seeking US companies who are interested in driving down the capital and operating costs in chemical manufacturing through the advancement of modular chemical process intensification. This will be done through the Manufacturing USA Institute known as RAPID. OMEP project lead David McFeeters-Krone is eager to talk with manufacturing firms that may fill capability gaps for these research programs, particularly module manufacturers and those skilled at metallic 3D printing, forming, and joining technologies.

OMEP will help manufacturers engage with the federally funded, billion-dollar research and development program Manufacturing USA. We are seeking US companies who are interested in driving down the capital and operating costs in chemical manufacturing through the advancement of modular chemical process intensification. This will be done through the Manufacturing USA Institute known as RAPID. OMEP project lead David McFeeters-Krone is eager to talk with manufacturing firms that may fill capability gaps for these research programs, particularly module manufacturers and those skilled at metallic 3D printing, forming, and joining technologies.

Small and mid-sized manufacturers play a vital role advancing modular chemical process intensification in the marketplace because they have a greater capacity to innovate manufacturing technologies and put them into practice. Further, the keen eyes and nimble processes of manufacturers are needed to determine manufacturability and commercial viability of new ideas.

In addition to seeking companies interested in championing and innovating through RAPID, OMEP will act as a gateway to thirteen additional Manufacturing USA sites. Focused on everything from smart materials to lightweight metals, these Manufacturing USA sites are pioneering new ideas in a variety of fields.

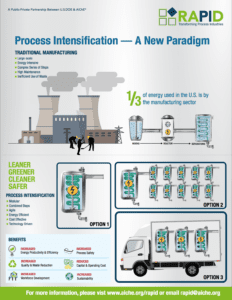

Why Focus on Modular Chemical Process Intensification?

Typically, chemical plants require city blocks worth of infrastructure, security, and logistical staging. RAPID follows the current trends to build and ship modular chemical plants to customer sites. This is similar to the conveniences manufactured homes brought to the housing marketplace. In chemical processing, process intensification technology can shrink the footprint of plants by combining multiple chemical processing steps into one or by leveraging accelerated transport phenomena to make chemical modules easier to build, transport and install.

Cheaper chemical modules open new markets for manufacturing modular chemical processing equipment. Projected volumes for this equipment could exceed tens of thousands of components and modules. Today’s prime integrators of chemical plants will require the nimble nature of small and mid-sized manufacturers to bring forward both the component manufacturing and the innovative know-how to design these new systems, as well as to establish key supply chain relationships.

RAPID has broken its modular chemical process intensification research into six focus areas:

-

Modeling/Simulation/Optimization/Control

-

Intensified Process Fundamentals

-

Chemical Module and Equipment Component Manufacturing

-

Natural Gas Upgrading Applications

-

Renewable Bioproducts Applications

-

Chemical and Commodity Processing Applications

Needs for these centers will evolve over time. However, if your teams are familiar with working with nickel-based superalloys, modular and equipment component manufacturing, or building chemical processing equipment we would love to hear from you. Take advantage of this new opportunity to stay on the cutting edge of technology and manufacturing advancement.

Contact

David McFeeters-Krone

Intellectual Assets, Corp.

OMEP Affiliate Consultant

503 493-0477 | dmk@intelassets.com