-

Don’t be afraid to try things

Follow the Plan Do Check Act model to make small iterations, and sustain positive changes.

-

Look for talent from within

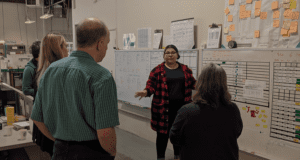

AmFor promoted a line worker to a more senior position due to her dedication and commitment to implementing lean and continuous improvement on the floor. She’s a great champion of lean with her co-workers.

-

Leadership is key is supporting change

This point relates to the last one. Make sure that as a leader you are hiring and firing based on your values. When there was resistance to the new promotion, the leadership team at AmFor advocated for their employee and supported her growth. Along the lean journey, the leadership team at AmFor stayed completely involved in the improvements from beginning to end. They reinforced and rewarded positive changes and new ideas.

-

Hold daily huddles to expose obstacles

Have open communication and work as a team. Use obstacles as growth opportunities and encourage open dialogue. This is crucial to help sustain change.

-

Just Do It

A half baked plan violently executed today beats a meticulously laid out plan that’s never implemented. Do and then iterate.

-

One Play at a Time

Things will go wrong, sometimes a change will make things go more slowly or too fast. That’s ok – adjust and run the play again.

-

If you can’t explain it to a 5th grader, you don’t understand it

Really seek to understand why and how lean works.

The hardest and least effective phrase in the Lean Manager’s toolkit is “Because I said so.”

A lean journey is the project of a lifetime, but AmFor has made great progress. Tour attendees also got to hear from OMEP’s Sheila Cuyler, who has been supporting them in their latest projects.

Stay tuned for more details on our next tour!

In the meantime, be sure to visit the Maker and Manufacturer Supply Chain Event >

Made Possible by:

For our first 2019 Learning Tour, hosted by

For our first 2019 Learning Tour, hosted by