Nearly fifty years ago, Shigeo Shingo (Toyota Motor Works Engineer) identified what he called the ‘primary forms of waste’. These forms of waste are nearly universally discoverable in every manufacturing environment.

The best definition of lean might be: “A systematic approach to identifying and eliminating waste…”

Simply identifying waste does not necessarily eliminate it. You need a systematic method to minimize or eliminate waste. But ‘step one’ is to identify waste; to develop observation skills capable of seeing non-value added activities and identify them as such.

Transportation

A manufacturing company I worked at recently with had five value streams operating in a 300,000 square foot building. We focused on only one value stream to start with. After performing the typical value stream mapping process, we added up the distance traveled by each person on the team. Each shift had 20 people and they operated three shifts, a total of 60 people per value stream. The average distance walked each shift was 3.8 miles.

This form of waste manifested itself in the movement of material between operations. While 3.8 miles does not seem like much, and after all, walking is healthy; however, when you measure the financial cost of walking 3.8 miles, times 60 people, times 250 days per year the total distance traveled is roughly 57,000 miles per year. This is the equivalent of paying 11 people to do nothing but walk.

Even more shocking when you realize that four other value streams were not even included in the calculation. The number of FTE (full time equivalent) walkers was probably somewhere between 50-60 (out of 360 people).

Motion

It may seem like motion and transportation are the same thing. However, we think about transportation as the movement of materials, information or people between operations. Motion is really the movement of those elements within an operation.

During my trip to Japan visiting over twenty different companies, I noticed a recurring theme. The facility layout of many of these organizations surprised me a bit. People’s desks and even machines were often arranged in what initially appeared to be a disorganized fashion. On our tours, we often had to duck and weave between equipment arranged at odd angles; seldom aligned, or perpendicular to the wall and other equipment. It seemed in disarray. I asked about the seeming lack of order.

Our host smiled and replied, “It may seem disorganized, but it is very efficient. If we aligned the equipment so that it looked absolutely parallel to the wall, or squared off with a secondary operation, it might require the operator to walk an additional 5 feet every cycle. This means after 400 cycles per day, 250 days per year the operator would unnecessarily walk 500,000 feet per year (10 miles). Multiply that by 500 people in the plant, and it makes sense to eliminate 5000 miles of walking by arranging the facility to minimize motion.”

Waiting

Waiting occurs everywhere, and in a cultural environment where people want instant gratification, our patients, clients, and customers are becoming less willing to wait. When an order is placed, it usually makes its way to somebody’s ‘in-box’, and goes to the bottom of the pile.

When completed at the first step, it moves the bottom of the pile at the next desk. If we can learn to practice the skill of ‘Pick-it-up-finish-it’, then the ‘start-stop’ method of processing is minimized as a contributor to the lead-time, backlog, waiting list or waiting line.

Inventory (or backlog of information, patients, customers)

A direct result of Over-production.

We are hard-wired from our youth to think in terms of batching. We make peanut butter and jelly sandwiches for our kids in batch mode. We lay out all the bread, we spread butter on all the bread, we add a layer of peanut butter to all the bread, and then we skim on a layer of jelly on each slice. Finally, we assemble the sandwiches and hand them to each child, who have all been impatiently waiting. If we make one sandwich at a time, there would be at least one child served, happy and no longer in line. Obviously, in the interest of fairness, you would need to alternate delivery during future sandwich building events.

In business, we often set up processes that serve the process rather than serving the patient, client or customer. We make them wait while we work on something that no one really requires at that time. We process as a ‘batch’ because we are set up to do so, and to change the process to meet the needs of the client standing in front of us means performing a set-up or change-over.

Imagine for a moment that you are going out to lunch. You have your heart set on a particular lunch item. However, when you arrive, the person taking orders informs you that they are currently making a big batch another lunch item. They tell you that you will have to come back an hour later, when they will be making your selection. You would be very disappointed and maybe not return at all.

Fast food restaurants are able to quickly assembly any lunch item because they have material prepared. TThe time required to changeover from one product to another is nearly zero. The intervention technique used to eliminate the need to ‘batch’ is referred to as SMED (Single Minute Exchange of Dies).

If we could eliminate (or minimize) the time it takes to change from one activity to another it would not matter how many changes in services, or products need to be delivered.

We could build and deliver on demand, one, instead of large lot sizes meant to amortize the cost and time of changeover.

Over-processing

They used to call this “Over-Gilding the Lily”. Doing more to a product or service than the customer really needs or more than they are willing to pay for. If I am buying a 2”x 8” piece of lumber to use as a planter box in my vegetable garden, I do not need it to be a painted – clear grade of mahogany as if I were installing it as the centerpiece of my living room fireplace hearth. I just need a common grade of pine, fir or hemlock lumber, knots and pitch pockets acceptable within reason. I do not want to pay $10 per foot; I expect to pay $10 for the entire board. Anything more would be over-kill.

Our customers and clients are the same. They do not want to pay for unnecessary services, over inspection or anything that needlessly adds to cost, but could be categorized as over-processing.

If I go into the barbershop for a haircut, I do not want them coloring my hair just to be able to charge me more. I want what I want; no more. This is not to say that going beyond the expectation or giving your customer something extra to excite them about being your customer is a bad thing, as long as they truly perceive it as something value added, something extra without charge; a bonus.

Over-production

After World War II, with the majority of other countries lying in ruins, the United States was the only real choice for customers seeking manufactured products. Our parents and grandparents had the markets cornered and with virtually no competition, there was little regard paid to machine maintenance, material optimization, labor utilization, inventory management or to minimizing the space occupied. We had plenty of each.

Companies ran machines as long and hard as they could. The bigger the batch size the better; every second spent in change over or ‘set-up’ was viewed as ‘opportunity lost’. They produced extra parts just in case, and never thought about inventory as a bad thing, in fact, the banks loved to see inventory on the books because it represented perceived value; money sitting on the shelves.

As Japan, Germany and other countries began rebuilding their countries and manufacturing capabilities, they had to do so with very limited resources. They were forced to consider how best to maximize space, minimize inventory, capitalize on labor and equipment utilization. US competitors have spent the last few decades playing catch-up with their foreign counterparts, reducing changeover times in order to reduce batch sizes and therefore inventory levels.

Defects

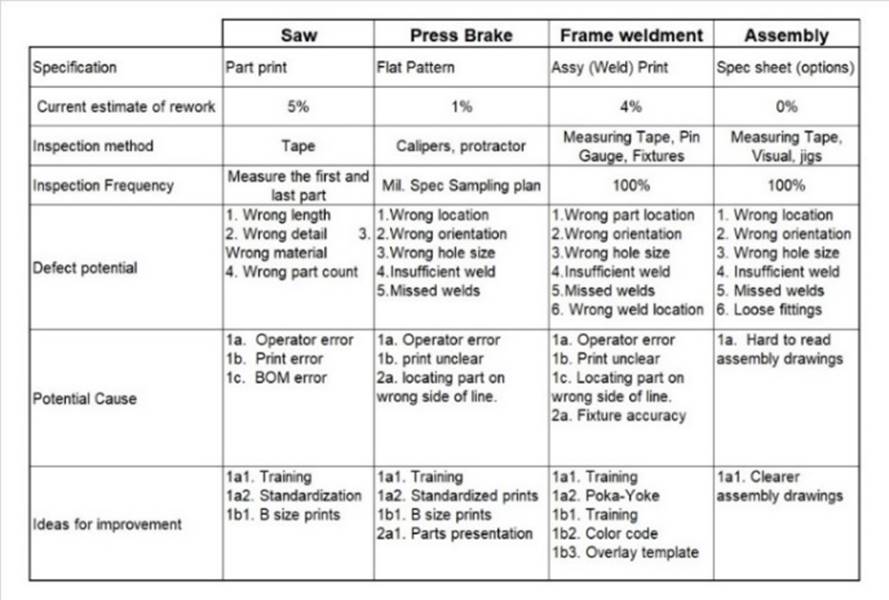

Defects are not just those products or services that ‘escape’ your process and create dissatisfied customers. Defects also include the in-house rework and rejects that you capture or reclaim between departments or processes. There are many Operational Excellence tools to help address the fall down of products or services. Quality mapping is one of the most effective tools in the toolbox. Like value stream mapping, quality mapping takes a deep dive into each process to identify and eliminate or minimize variation what could possibly lead to a defect.

Figure: Quality map example

Under-utilization of talent

Every organization must manage many inputs to their process; material, facilities, financial resources, machines and the human resource (people) just to name a few. The most variable input of all these resources is people. No two people are exactly alike; we are not robots; therefore, there is inherent variation, and that variation is not completely controllable.

On the positive side, the variation in talent, education, experience, work ethic, ethnic background, motivators and attributes provide a rich and diverse population capable of contributing ideas that robots cannot. Learning to manage and capitalize on the diversity and talent of the team can be a challenge as well as a rewarding and satisfying experience. In the Japanese culture, it is an expectation that everyone on the team works hard to develop ideas for improvement every day.

This is not the case in many American organizations. Therefore, the talent, ideas, and creativity of the workforce is many times spent in idle daydreaming about what activities the weekend might bring.

How can our teams be motivated to fully engage their minds in searching for productivity improvements? What is their motivation for doing so?

An experience during my journey to Japan in the late 1990s netted me a very significant realization about the differences in our cultures.

I was walking the streets of a Japanese city one early morning in search of a cup of coffee. During my walk, I came across a motorcycle, parked on the sidewalk, sitting on its kickstand, key in the ignition. It occurred to me that someone might lose a nice motorcycle; however, having no ability to speak Japanese, there was precious little I could do about it at four o’clock in the morning.

A few blocks later, I walked by a car that had all of the windows rolled down. I was shocked to see the keys dangling from the ignition. Later that morning I described what I had seen to our tour guide. She nodded and acknowledged that what I had observed was not unusual. She explained, “In our culture, it is nearly unheard of to steal something; to do so would dishonor our family for hundreds of years into the future (and the past).”

As I visited with people in twenty different companies, talking with them about the countless ideas they came up with, I continually asked how and why did they spend so much time focusing on idea generation. The answer from one ‘thirty-something’ woman surprised me, she said: “I want my great grandson to be able to have a job when he enters the workforce. I want this company to still be here when he is old enough to go to work.”

I was doing math in my head, thinking, “There is no way this lady has a great-grandson!” However, she was thinking a hundred years ahead. Our competitors are long-term thinkers.

What is our thought process regarding the future? “End of the week? End of the month? End of the fiscal year? A four-year political system?”

We tend to be rather short-term thinkers. If we are going to maximize talent and eliminate the underutilization of our most important resource, we must fully engage, enfranchise and encourage creativity in our teams. These primary forms of waste provide a target rich environment for people trained to identify and eliminate them.

OMEP works within all manufacturing environments to develop strong observations skills and intervention techniques. If you’re interested in a free assessment, let us know.