OMEP is seeking manufacturers capable of precision bonding Inconel 625 as part of our work with RAPID.

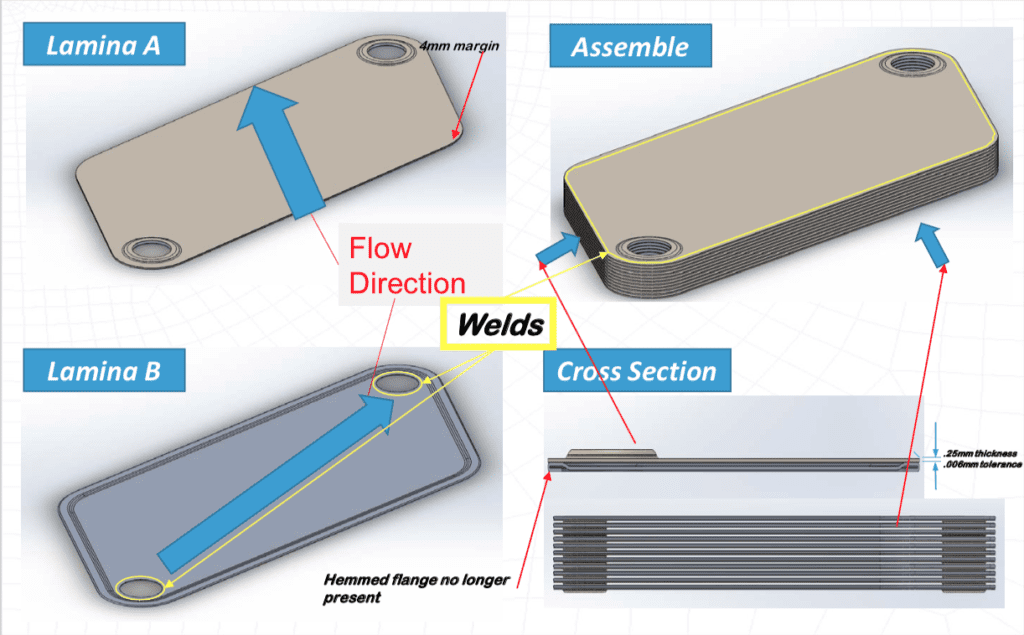

The application is to bond multiple layers of 0.5mm Inconel 625 to form a microchannel plate and frame heat exchanger. The design is substantially similar to the photo on the left. Bonding is required between lamina A and B.

- At the periphery (note lamina B has a raised flange to meet the bottom edge of lamina A) and

- Around the edges of the two embossed holes in lamina A (raised to meet the bottom of lamina B)

Other important notes

- These plates will be stacked with 8 pairs + 1.

- Final design will have supporting ridges at same height as welding boss in lamina A.

- Cross-sectional height tolerances of 0.5 mm tall channels are 15 micrometers (key).

- 2 to 4 assemblies will be procured.

- Hemmed flange in picture has been designed out.

If you are interested in this opportunity, please contact David McFeeters Krone at dmk@intelassets.com or call him at 503 493-0477 (work)